As the adoption of lithium-ion (Li-ion)

battery systems continue to rise in South Africa, so too does the risk of

electrical fires.

As the adoption of lithium-ion (Li-ion)

battery systems continue to rise in South Africa, so too does the risk of

electrical fires.

“Li-ion batteries pose unique fire risks due to their chemical composition and the environments in which they are used,” explains Eldon Kruger, Marketing Director at Pratley. “Overheating, electrical faults, and poor ventilation are all factors that can lead to fires. However, with appropriate battery room construction and fireproofing these risks can be significantly mitigated.”

Li-ion battery fires often stem from thermal runaway, a chain reaction triggered by overcharging, physical damage, or internal short circuits. The flammable electrolytes in these batteries and the heat generated in enclosed spaces exacerbate the danger. Electrical malfunctions such as faulty wiring or overloaded circuits further increase the risk, especially in facilities where room fireproofing has been neglected.

Designed for fire safety

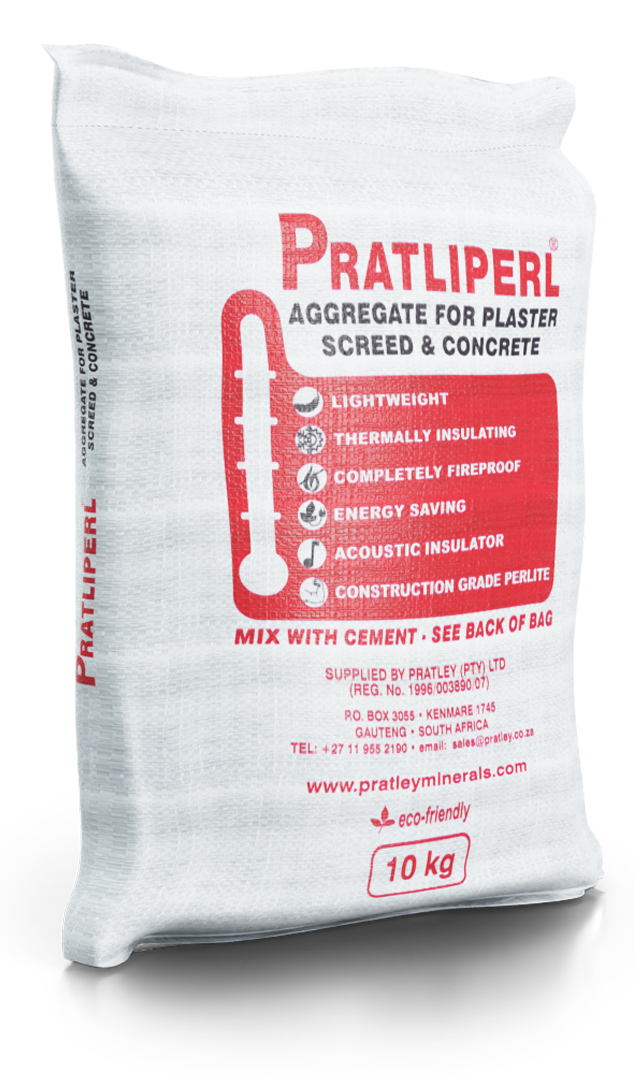

The importance of fireproofing modern

battery rooms is a key component in fire safety. Pratliperl® is a non-combustible, ultra-lightweight

aggregate that can be mixed with cement and applied as a plaster or screed to

walls, floors, and ceilings. When applied at just 30 mm thickness, Pratliperl®

delivers a two-hour fire rating, as certified by the South African Bureau of

Standards (SABS).

The importance of fireproofing modern

battery rooms is a key component in fire safety. Pratliperl® is a non-combustible, ultra-lightweight

aggregate that can be mixed with cement and applied as a plaster or screed to

walls, floors, and ceilings. When applied at just 30 mm thickness, Pratliperl®

delivers a two-hour fire rating, as certified by the South African Bureau of

Standards (SABS).

“What sets Pratliperl® apart from traditional fireproofing materials is that it releases no toxic smoke or fumes during a fire,” highlights Kruger. “This not only protects infrastructure but also provides a safer environment for anyone in or near the affected area.”

Seamless integration and long-term benefits

Pratliperl® is

designed for both new and existing battery room setups, offering a

cost-effective fireproofing solution that integrates easily with current

systems. “We recommend plastering battery rooms with Pratliperl® and sealing

all cable and conduit wall penetrations to prevent fire from spreading through

gaps,” adds Kruger. “When combined with proper ventilation and extraction fans,

the result is a comprehensive fire safety strategy.”

Pratliperl® is

designed for both new and existing battery room setups, offering a

cost-effective fireproofing solution that integrates easily with current

systems. “We recommend plastering battery rooms with Pratliperl® and sealing

all cable and conduit wall penetrations to prevent fire from spreading through

gaps,” adds Kruger. “When combined with proper ventilation and extraction fans,

the result is a comprehensive fire safety strategy.”

In the long term, Pratliperl® helps to maintain the structural and electrical integrity of battery rooms. It slows the spread of fire, protects adjacent equipment and infrastructure, and reduces downtime and costs associated with fire-related damage.

Fire safety is not just about compliance, it is about protecting people, property, and uptime. “With Pratliperl®, facility owners and engineers can take proactive steps to prevent disaster before it strikes,” concludes Kruger.